- In order to increase the life time of the switching power supply, we recommend users to choose a model which has rated output 25% more than actual need. For example, if a system required a power supply for 200W, we recommend the users to choose a power supply that has 250W rated power. This is to increase the life time and reliability of power supply.

- Please make sure the power source is 115V or 230V, if your system sell to all over the world, we recommend users choose some type with universal input(115~230V) or 115V/230V Auto sensing. It will fit all over the world.

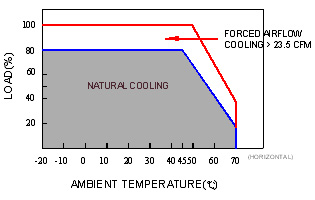

- To estimate the working temperature of Power Supply, and extra forced cooling equipments. When a power supply works at higher temperature environmental, it needs to lower the output power requirement. About the curve changes between the temperature ambience & rated output power load, please refer to the product specification.

- Read the specification of your power supply to understand all functions and the size that fit your requirement.

- According to your applying conditions may choose the protection function you required:

- Protection function: over voltage protection(OVP)、over load protection (OLP)、over current protection(OCP)、over temperature protection(OTP) , etc…

- Application function : signal function(POWER GOOD 、 POWER FAIL)、remote control On/Off function、remote sense function、output in parallel function , etc…

- Special function: power factor correction (PFC)

- Make sure that the model qualifies for the safety standards and EMC regulations you need.

- It’s should be noticed that the air flow of the installation position is well, whatever the power supply is natural cooling or forced cooling.

- When using the Class I products, make sure that the PE and ground is connecting to avoid leakage current and get an electric shock. If using Class II products that the power supply only has L,N input connecter without PE to ground, it does not need to connect to ground.

- The connecting wires should be shorter and the users need to notice the current range to avoid wire loss too high to lower the output voltage.

- If users choose the natural cooling fanless power supply and the air flow situation is bad that make internal temperature too high, it needs to add a cooling fan to assist system cooling.

SUNPOWER’s engineer consider the demands of variety kinds of system, we have indicated the max. current for each outputs. But users still need to aware of the total output wattage, should not over the loading limit.

- Single output:positive pole(+V),negative pole(-V)

- Multi output:According to channels (V1,V2,V3………), ground(GND)

- Isolation output:According to channel V1.G1 and V2.G2………

Because of different circuit designs, power supply’s input consists of three types as below:

- 85~264VAC or 120~375VDC

- 176~264VAC or 250~375VDC

- 85~132VAC / 176~264VAC by Switch;250~375VDC

- In (a) and (b) inputs models, power supply can work properly no matter under AC or DC input. But it needs to notice that some models are designed like: positive pole connects to AC/L; negative pole connects to AC/N. And the power supply may turn on properly. If customers make a wrong connection, the power supply will not be broken. You can just reverse the input poles and power supply will still work normally.

- In (c) input models, please make sure that you change the 115/230V switch to 230V position and then correctly input 250~375VDC. Please be awarded if, the switch is selected on the 115V and the real input is 230V, and then the power supply will be damaged. Please be awarded.

PFC stands for Power Factor Correction. The purpose of PFC is to correct & reduce the ratio of apparent power and real power. Without PFC, the power factor has about 0.45 ~ 0.6 actual. With active PFC types, the power factor can be reached about 0.95. The description formulas are as below:

Apparent Power (VA) = Input Voltage x Input CurrentReal Power (W) = Input Voltage x Input Current x Power Factor

From the users point, the Electric Power Plant needs to generate a power, which is higher than Apparent Power to the electricity users. The actual usage of electricity should be defined by real power. If the power factor is 0.5, the Power Plant needs to produce more than 200VA to a 100W real power needs. On the other way, if the power factor is 0.95, the Power Plant only needs to generate more than 105VA to provide a 100W real power needs. It will be more efficient to use electric energy. And the power source can also reduce the input current too. Meanwhile, higher power factor means can be reduced the loading of Power Plants. It can also reduce power disturbances by current harmonic wave in power supply and make higher quality of electric power to avoid damaging the facility which been connecting to power supply.

Here is a comparative table between SPS-150P-12 with active-PFC and SPS-G150-12 with non-PFC when output is 12V/12.5A below:

| Model No. | PFC type | input(V) | input(A) | input(VA) | input(W) | PF |

|---|---|---|---|---|---|---|

| SPS-150P-12 | Active | 115 | 1.61 | 185.79 | 183.0 | 0.985 |

| 230 | 0.79 | 183.13 | 178.0 | 0.972 | ||

| SPS-G150-12 | --- | 115 | 2.68 | 308.82 | 178.5 | 0.578 |

| 230 | 1.46 | 337.19 | 175.0 | 0.519 |

The current coming from power supply through the wires has resistance occur. And such resistance will cause to lower potential and has potential difference. There are three way to solve this problems that we recommend users (1) reduce the length of connection wires (2) change the wires to bigger diameter (3) use SUNPOER’s power supply which has Remote Sense function, and it can higher the potential, to let the ends of wires supply 5V remainly.

For SPS-230P-05 as an example:If we make it output 32A,connecting with 50cm wires,the wire loss are below:

| AWG Cable dia. | 50cm Wire Loss (Voltage drop) |

|---|---|

| 10 | 0.114 |

| 12 | 0.184 |

| 14 | 0.294 |

According to the Safety standard, the leakage current in EN60950-1 Class I cannot exceed 3.5mA; in EN60601-1 the leakage current cannot exceed 300μA. The safe distance and numbers of fuse are also different when measuring.

The difference detail is below:| Subjects | IEC60950-1 | IEC60601-1 | ||

|---|---|---|---|---|

| Creepage distance/Clearance distance | Basic insulation ≧ | 2.5mm / 2mm | 4mm / 2.5mm | |

| Workingvoltage:250Vrms(Max.) | Supplementary insulation ≧ | 5mm / 4mm | 8mm / 5mm | |

| Electric strength test | Basic insulation ≧ | 1500Vac | 1500Vac | |

| Supplementary insulation ≧ | 3000Vac | 4000Vac | ||

| Leakage current | Class Ⅰ≦ | Handheld type: 0.75mA | - | |

| other 3.5mA | Leakage current of ground | 300μA | ||

| Leakage current of case | 100μA | |||

| Class Ⅱ≦ | 250μA | Leakage current of case | 100μA | |

| Number of fuse | Class Ⅰ | 1 | 2 | |

| Class Ⅱ | 1 | |||

| Operating Temperature | By manufacture defined | ≧ 40 ℃ | ||